Хатогии формати почтаи электронӣ

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Automotive Engine Cooling System Temperature Sensor

Similar to a PTC thermistor, the KTY temperature sensor is a silicon sensor with a positive temperature coefficient. The resistance to temperature relationship is, nevertheless, roughly linear for KTY sensors. Manufacturers of KTY sensors may have different operating temperature ranges, although they commonly fall between -50°C and 200°C.

The KTY temperature sensor is a silicon sensor that also has a positive temperature coefficient, much like a PTC thermistor. However, for KTY sensors, the relationship between resistance and temperature is approximately linear. Operating temperature ranges for KTY sensor manufacturers may vary, but typically range from -50°C to 200°C.

The Features of Automotive Engine Cooling System Temperature Sensor

| Alumina Shell Package | |

|---|---|

| Good stability, Good consistency, moisture resistance, high precision | |

| Recommended | KTY81-110 R25℃=1000Ω±3% |

| Working Temperature range | -40℃~+150℃ |

| Wire Recommend | Coaxial Cable |

| Support | OEM, ODM order |

The resistance value of LPTC linear thermistor increases with the increase of temperature, and changes in a straight line, with good linearity. Compared with the thermistor synthesized by PTC polymer ceramics, the linearity is good, and there is no need to take linear compensation measures to simplify the circuit design.

KTY series temperature sensor has simple structure, stable performance, fast action time and relatively linear resistance temperature curve.

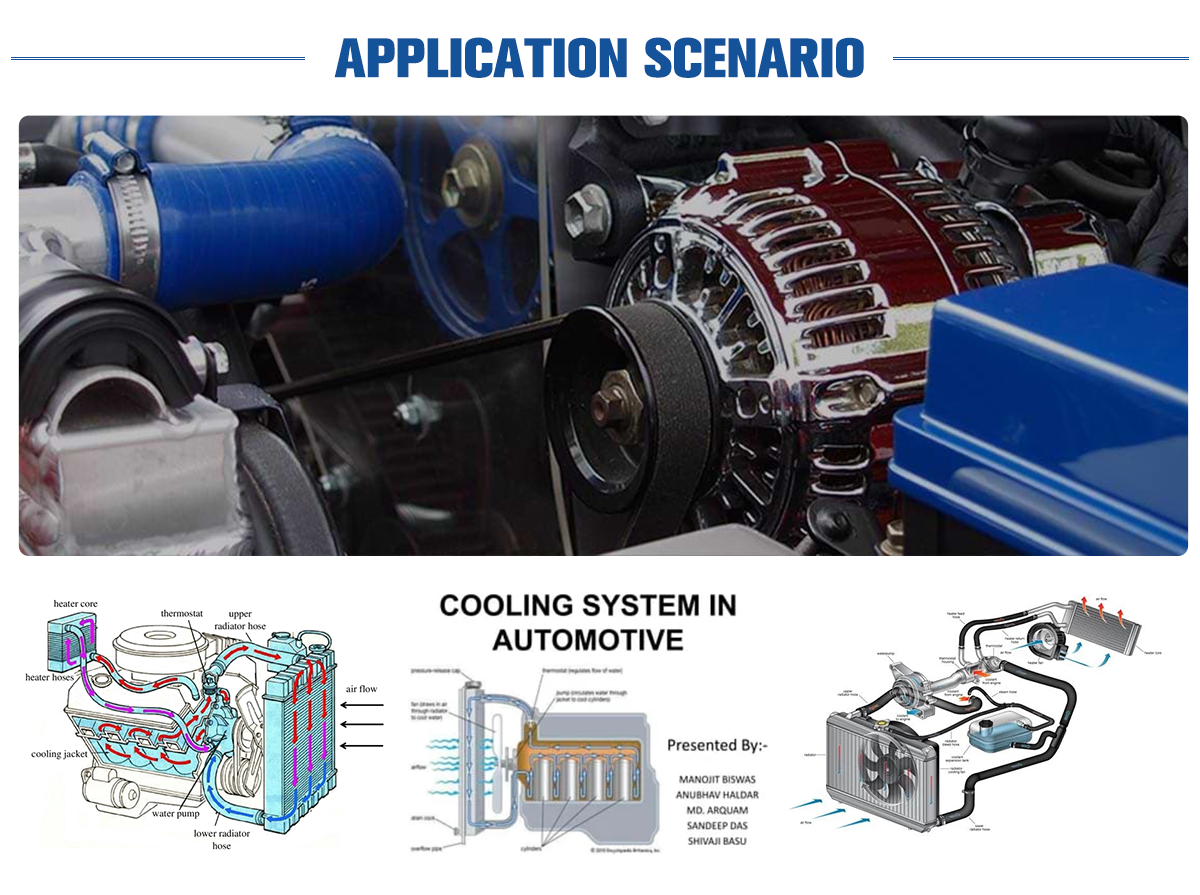

The Applications of Automotive Engine Cooling System Temperature Sensor

Automobile oil temperature, water temperature, solar water heater, engine cooling system, power supply system

The Role of Engine Cooling System Temperature Sensor

Another type of positive temperature coefficient sensor is a silicon resistive sensor, also known as a KTY sensor (a family name given to this type of sensor by Philips, the original manufacturer of the KTY sensor). These PTC sensors are made of doped silicone and are fabricated using a process called diffused resistance, which makes resistance nearly independent of manufacturing tolerances. Unlike PTC thermistors, which rise sharply at the critical temperature, the resistance-temperature curve of KTY sensors is almost linear.

KTY sensors have a high degree of stability (low thermal drift) and a nearly constant temperature coefficient, and are also generally less expensive than PTC thermistors. Both PTC thermistors and KTY sensors are commonly used to monitor winding temperature in electric motors and gear motors, with KTY sensors being more prevalent in large or high value motors such as iron core linear motors due to their high accuracy and linearity.